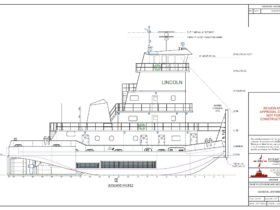

Because of our reputation for delivering a quality product on time and on budget, Shaver Transportation selected Vanport to fabricate and install the Level 4 section of the pilot house on the tug Lincoln which received an upgrade and retrofit that took place at the Diversified Marine, Inc. Portland facility.

Shaver acquired the 90’ long, 3,000 horsepower, pusher tug to add to its Columbia River fleet to move barges filled with grain. Often times, several barges are rafted together fore to aft so having good site lines is crucial to the successful navigation off the Columbia River system and for this reason, Shaver desired to raise the height of the pilot house.

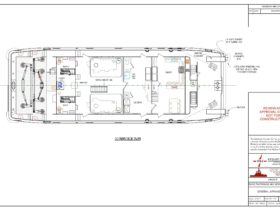

Our project manager worked closely with Herb Stephens of Wyeast Marine, the project’s Naval Architect, to measure the vessel and confirm the structural layout of the vessel in order to properly design and fit up the new fabrication. Our crew of trained welder fabricated the main structure, stairways, ladders, and the exterior deck in our climate controlled facility and readied it for transport to the site. Once on the site, our team worked with employees of DMI to lift the structure in to place. After being craned into position, the house structure was field welded by our team of welders and fitters.

Today, the vessel is hard at work on the river system thanks to the teamwork of the Shaver Transportation, Diversified Marine, Inc., Wyeast Marine, and Vanport Marine.