March 2024

Vanport has obtained a new High-Definition CNC Plasma Table. Vanport selected the manufacturer ShopSabre for a variety of reasons.

- Their equipment is Made in the USA, Minnesota specifically.

- Their equipment presented a fair value amongst competitors regarding capabilities versus cost.

- Their website offered plenty of online tutorials for running the equipment as well the programming software.

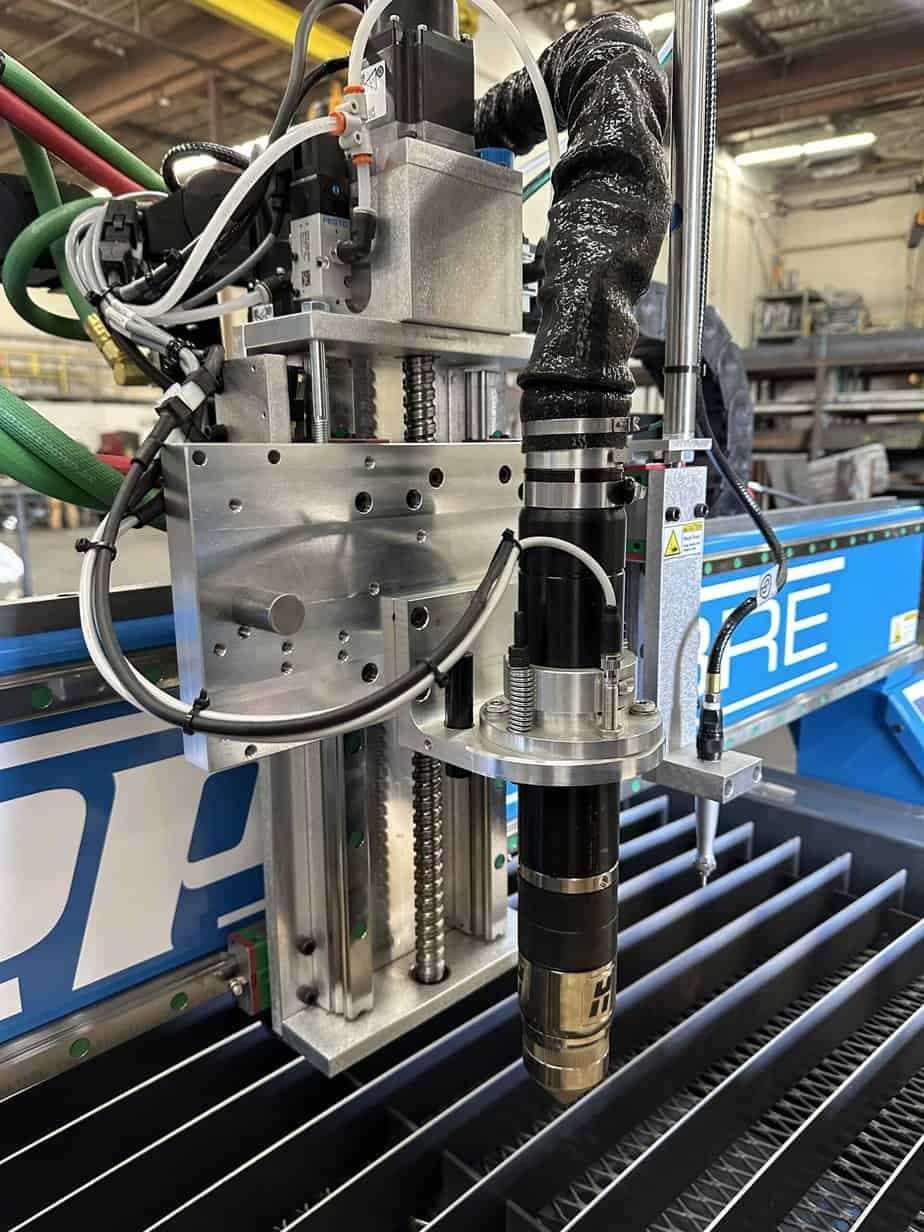

We selected the ShopSabre ShopMaster Pro 10 Plasma System equipped with the following,

- Fully Assembled Steel Frame

- Steel Gantry with Tube Steel Gantry Uprights

- Industrial Precision Anti-Backlash Center Mounted Ball Screws Z Axis

- Industrial Precision Rack and Pinion with Planetary Drive on XY Axis

- Digital Brushless A/C Digital Servo Upgrade with Amplifiers – Increase Machine Speed to 2000IPM (X, Dual Y,Z Axis)

- Industrial 25MM Precision Linear Guide Rails & Bearings

- ShopMaster Breakaway Z Torch Mount with Level for Torch Alignment

- HD Electronic Torch Collision Detection w/ Emergency Stop

- Advanced Digital Torch Height Control with Auto Touch System (THC) and Touch Distance Control Technology

- ShopSabre Rolling Enclosed Steel Fan Cooled Machine Operator Control Stand

- XY Laser Sights

- Pneumatic Scribe Attachment (For Parts Labeling)

- Oxy-Fuel Torch Attachment (for Carbon Steel Plate greater than 2-3/8”)

- 60″ x 120″ Effective Cutting Area

The cutting capabilities of the table are powered by a new Hypertherm XPR170 HyPerformance Plasma Unit with AutoGas Solution.

- The next generation Hypertherm XPR plasma represents the most significant advancement in plasma cutting technology, ever. The XPR offers unmatched X-Definition cut quality on mild steel, stainless steel, and aluminum. The XPR increases cut speed, and dramatically improves productivity while slashing operating costs.

- Precisely Cuts Mild Steel Plate up to 2-3/8″ Thick

- Precisely Cuts Stainless Steel Plate up to 1-1/2″ Thick

- Precisely Cuts Aluminum Plate up to up to 1-1/2″ Thick

Upon receipt of the unit we assembled it in our shop and flew out a technician from ShopSabre to provide hands-on training for the machine. We are very excited to have such a well-made and well-performing machine at our disposal. Simply put, the machine will allow us to meet construction tolerances with less work, saving us time and saving our customers money. As we also run AutoCAD to produce shop drawings, we have the ability to export our DXF files from the 3D models themselves, saving a step in the programming process.