Despite Vanport usually serving as a General Contractor, we never shy away from supporting like-minded contractors in a subcontractor role. That was just the case for this project. Hunter-Davisson, a well-known and highly reputable HVAC contractor, requested our support for the turnkey delivery of renewing (3) large chiller units for their customer out in Camas Washington. As a long-term customer Hunter-Davisson knew we could be trusted to deliver top-notch pipefitting, resourceful & safe rigging techniques, and effective project management to ensure their schedules would be met.

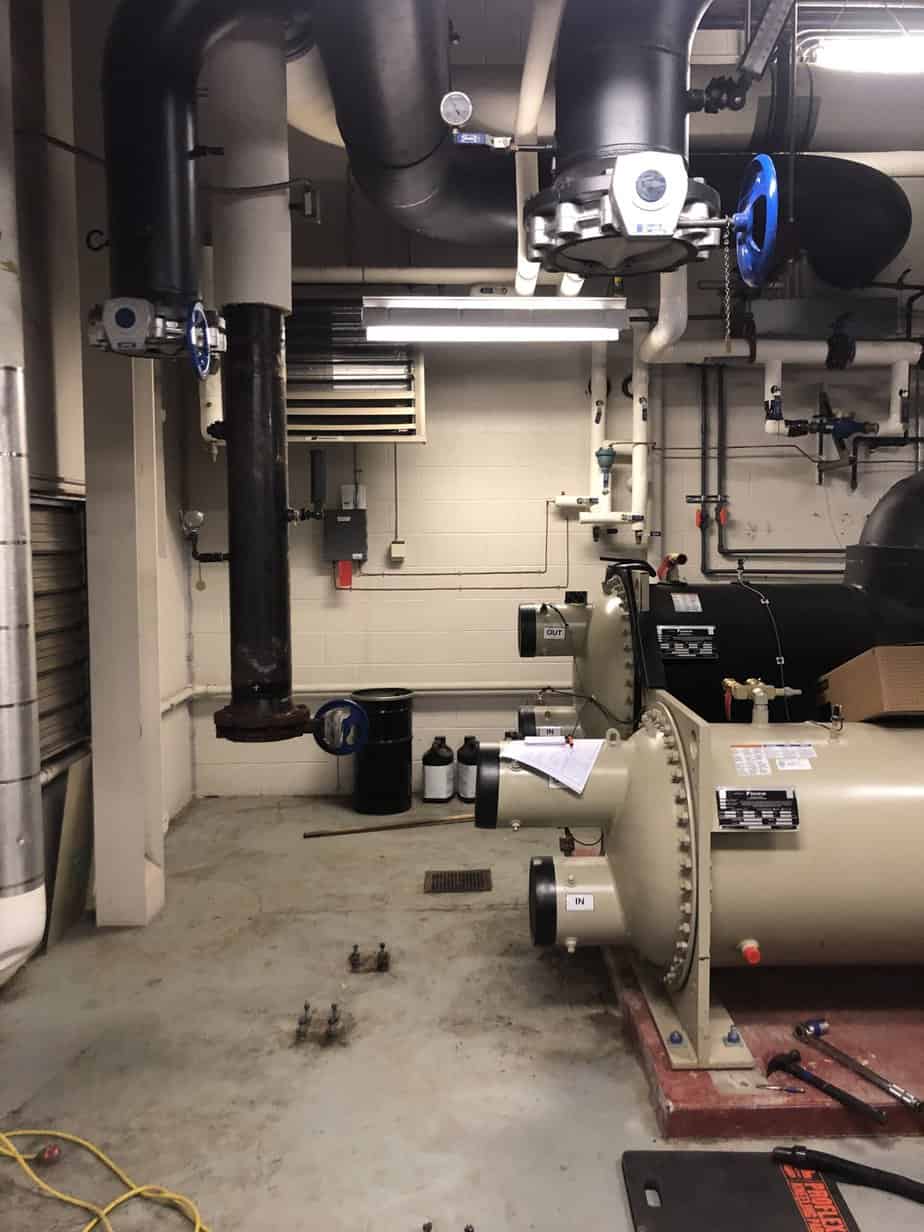

The project itself entailed mostly carbon steel piping modifications, ranging from 8” pipe to 12” pipe. Within the chiller room were other modifications to perform such as renewal of 20” Automatic Flow Valves, 12” Section Strainers, and some smaller Remote Actuated Butterfly Valves. In addition, we also handle the venting of each unit which simply consisted of small 3” SCH40 piping. Due to the weight of piping and present building code, all assemblies were equipped with seismic supports which we fabricated and installed as well.

All welding and fitting was done on-site, however proper equipment was deployed to “bring the shop to the field”. We feel that this decision saved us and our client considerable time by eliminating material transports from the shop to the field. Furthermore, while subtle, it gave us a visual presence on the project which enabled Hunter-Davisson’s customer to see for themselves that their project was being actively being worked and that at all daily milestones Hunter-Davisson communicated were being met.

The project concluded with testing, which of course went very well. This was a great project to assist with because our customer was very good to work with and site conditions were exceptionally spacious.